HIGHLIGHTS

PROGRAM UPDATES

Think Wood Mobile Tour Welcomed at Virginia Tech for National Forest Products Week WoodWorks Helps Convert Tall Mass Timber Interest Into Completed Buildings The AWC Discusses Mass Timber With Utah Fire Chiefs and East Coast Designers, ArchitectsINDUSTRY NEWS

Student-Designed Mass Timber Pavilion Set to Travel Through Georgia The Architect’s Newspaper’s Mass Timber Issue Surveys the Latest Timber Innovations Hot Remodeling Industry Poised to Cool Down Hybrid Timber Adaptive Reuse Project Turns Austin Warehouse Inside OutINSIGHTS ON THE COMPETITION

Can Our Buildings Be Recycled?Program Updates

Think Wood Mobile Tour Welcomed at Virginia Tech for National Forest Products Week

A new video produced by Virginia Tech showcases the relationship Think Wood has developed with faculty on campus to bring information about low-carbon wood construction to architecture students. The video features professors Edward Becker and Daniel Hindman discussing how they are integrating their own professional research on wood construction into their curricula, and how Think Wood and the SLB have been integral to creating connections between the work occurring in academic studios and the broader industry.

As a complement to an existing exhibit about mass timber featuring student work, the Think Wood Mobile Tour visited the Blacksburg, Virginia, campus to bring practical demonstrations of wood and mass timber products and applications to the students and campus community. The Mobile Tour arrived on October 15 to tailgate during the highly anticipated homecoming game—and to share the information about the benefits of wood construction during Forest Products Week.

On October 17, the display relocated to Cowgill Hall, which hosts faculty offices, classrooms, and undergraduate and graduate architecture studios. Mobile Tour personnel offered tours to the architecture faculty and students, and drew connections to the mass timber exhibit at the school as well as to the mass timber-related studios being run by professors such as Becker and Hindman. Besides being an advocate for mass timber, Becker was a presenter at the SLB-funded Timber Design Faculty Development Workshop held in May at Clemson University. He was instrumental in bringing the Mobile Tour to VT.

WoodWorks Helps Convert Tall Mass Timber Interest Into Completed Buildings

WoodWorks continues to evolve its technical support to capitalize on recent wood-friendly code developments and to help developers and designers translate their interest in wood into fully realized projects.

The adoption of the 2021 tall timber code provisions and the more recently approved adjustments to the 2024 IBC—all championed by the American Wood Council (AWC)—combined with a growing interest in wood, fueled by Think Wood’s communications and lead nurturing efforts, have helped to create more calls for WoodWorks’ technical assistance in the market. In Q3 2022 alone, WoodWorks began consulting with teams on 21 new tall mass timber projects. Year-to-date, it has supported 70 new tall mass timber projects, bringing the overall total to 180.

In Q2, WoodWorks also welcomed the advancement of several high-profile projects: the Minnesota Places project in Portland, Oregon, broke ground; Phase 1 of INTRO officially opened in Cleveland; and the 25-story Ascent building in Milwaukee was certified as the world’s tallest mass timber hybrid building. Online publication Vox recently published the feature video How to Build a Wood Skyscraper, which provides a closer look at Ascent and the tall mass timber construction process, including insights from Ricky McLain, WoodWorks’ Senior Technical Director of Tall Wood.

In addition to project assists, WoodWorks continues to provide high-quality education and targeted meetings within the architecture, engineering, and construction community to solidify its reputation as the tall mass timber experts in the U.S. and a go-to resource for mass timber project advice and support.

The AWC Discusses Mass Timber With Utah Fire Chiefs and East Coast Designers, Architects

The AWC’s Fire Protection Engineer Ken Bland covered a lot of ground discussing mass timber construction with fire service leaders and design professionals. He presented to the Utah Fire Chiefs Association’s fall business meeting. In speaking to 80 fire chiefs from around the state, Bland discussed the tall mass timber provisions contained in the Utah Building Code, which was modified by the Legislature in May 2020 to make tall mass timber permissible throughout the state. Several chiefs shared that mass timber projects were already underway in their jurisdictions. The presentation provided fire officials with a better understanding of the rigorous fire testing that has been done on mass timber, helping to mitigate some initial safety concerns for this new type of construction.

Bland also delivered a virtual presentation at the third annual Advancing Mass Timber Construction 2022 conference in Boston. For this audience of more than 150 architects, engineers, and stakeholders with an interest in tall mass timber, Bland tailored his presentation on the 2024 code changes and the impact on design innovation. His presentation also highlighted the extensive fire testing that underpinned the mass timber changes to the 2021 and 2024 International Building Code. Attendees also received strategies and technical resources to use when approaching building and fire officials with mass timber structure plans.

Industry News

Student-Designed Mass Timber Pavilion Set to Travel Through Georgia

The future leaders of mass timber architecture in the Southeast and beyond might be sitting in Georgia Tech’s classrooms. Through a partnership with the Georgia Forestry Foundation (GFF) and the SLB, supported by a grant from the USDA Forest Service, Georgia Tech’s Digital Fabrication Lab hosted a Mass Timber Design Studio this year that brought together students in architecture, civil engineering, and construction management to develop designs for a mass timber exhibition. The student teams developed designs and models for a pavilion that can be moved across the state to raise awareness about the benefits provided by mass timber and sustainable forest management in the South.

Earlier this year, the SLB had also sponsored the annual South Quad Conference of the American Institute of Architecture Students held at Georgia Tech and included a guided tour by SLB and GFF of CLT manufacturing at the Lab.

The school released the final design for the pavilion in August, and a new flyover video provides an immersive look at the renderings. Dubbed “Tim(ber) Mobile” by its creators, the design features a wing-like canopy with charred timbers to demonstrate the material’s fire resilience. It includes spaces for mass timber education along with a small garden and a stage.

The Georgia Tech team also designed a smaller pop-up mass timber display intended to be installed at Ponce City Market in Atlanta by February, when panels start going in for the new 619 Ponce mass timber building developed by Jamestown with architect Handel Architects and engineer StructureCraft.

Learn more about the mass timber pavilion project here.

The Architect’s Newspaper’s Mass Timber Issue Surveys the Latest Timber Innovations

Now in its fourth year, The Architect’s Newspaper’s annual mass timber issue provides a deep, valuable resource covering new developments in timber design and construction. In addition to showcasing winners of the SLB and USDA Forest Service’s 2022 Mass Timber Competition and recapping the Think Wood-sponsored TimberCon virtual event, the issue features product coverage and case studies, as well as an in-depth Q&A with Pritzker Architecture Prize laureates Yvonne Farrell and Shelley McNamara of Irish firm Grafton Architects.

Farrell and McNamara discuss their design for the Anthony Timberlands Center for Design and Materials Innovation, a research facility at the University of Arkansas developing new products for the state’s timber industry. The architects’ design showcases a variety of local species and timber components, including heavy white oak timbers, glulam beams, cross laminated timber panels, a black locust façade, and cypress parts—all sourced from state forests.

“This project is fantastic because it’s both a building and a teaching tool,” Farrell says in the interview. “That’s what we were fascinated by. The competition was written in a way that the building would become one of the teachers of the wooden architecture. How do you do research about and gain experience with this material? The university is passionate about their students learning about timber, so there was a lot of dovetailing of interested parties to move forward towards a more sustainable future.”

Hot Remodeling Industry Poised to Cool Down

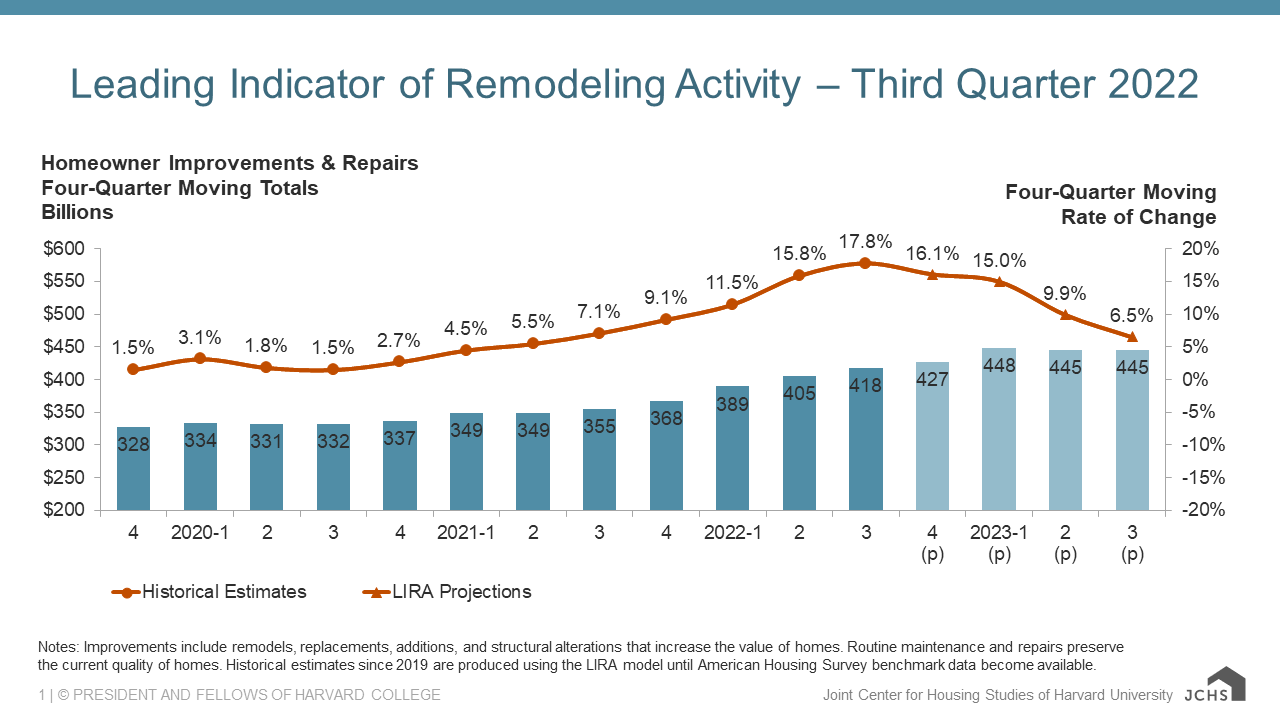

Growth in remodeling activity is projected to slow down in 2023 after rising this year at the highest rate since 2005, according to the Leading Indicator of Remodeling Activity (LIRA) from the Remodeling Futures Program at the Joint Center for Housing Studies of Harvard University. Year-over-year homeowner remodeling and repair spending is projected to grow 16.1% in 2022, but that growth is projected to shrink to 6.5% in the third quarter of 2023.

“Housing and remodeling markets are undoubtedly slowing from the exceptionally high and unsustainable growth rates that followed in the wake of the pandemic-induced recession,” says Carlos Martín, Project Director of the Remodeling Futures Program at the Center, in a press release. “Spending for home improvements will continue to face headwinds from declining home sales, rising interest rates, and the increasing costs of contractor labor and building materials.”

Despite those headwinds, the program projects that the remodeling market will grow to nearly $450 billion in 2023, supported by record levels of home equity to support renovation financing, energy-efficiency retrofits incentivized by the Inflation Reduction Act of 2022, and disaster repairs and mitigation projects following Hurricane Ian.

Hybrid Timber Adaptive Reuse Project Turns Austin Warehouse Inside Out

How do you take the footprint of an existing warehouse and transform it into a vibrant, light-filled environment that welcomes the broader community? For Gensler, the solution was simple but surprising: Turn the building inside out.

That was the approach the architects took for Fifth + Tillery, a wellness-focused office building at a post-industrial site in East Austin, Texas. The design carves a central courtyard through the space, bringing core functions to the exterior and introducing landscaping to the warehouse footprint. The landscaping created rich public spaces that connect the building to the spirit of the neighborhood.

Reducing the overall carbon footprint was a goal both of the project and of Gensler’s Cities Climate Challenge, which aims to eliminate all carbon emissions from the firm’s work by 2030. The design reduces embodied carbon by reusing much of the existing structure and, for the new building, utilizing a hybrid timber structure with long-span glulam paired with steel columns and concrete over a long-span metal deck. Cuts from the glulam structure were repurposed as benches throughout the project’s public spaces.

Learn more about the project and Gensler’s collaborative approach here.

Insights on the Competition

Can Our Buildings Be Recycled?

The dream of the circular economy is inspiring: If everything we create can be designed with reuse in mind, then very little needs to be thrown away. In an in-depth feature, The New York Times profiles two leading proponents of the circular economy in the design and construction community, illustrating both the opportunities and extensive challenges communities face as they seek to encourage recycling and reuse.

The reporter visits Amsterdam, which has become a hub for the circular economy and where the city government has announced plans to start building a fifth of new housing with wood or bio-based material by 2025 and to halve the use of raw materials by 2030. “City officials have run into the bottlenecks that circularity advocates face everywhere,” the reporter says. These issues include: “how to develop and pay for the specialized labor needed to deconstruct and refurbish old materials; where to store the materials as they are being updated for their next iteration; how to gather enough data about existing buildings and their demolition schedules to be a useful resource for designers.”

Wood construction and material reuse will certainly both play a global role as solutions to the environmental problems of growing waste and embodied emissions for new construction. The choices that designers make about material reuse also bear monitoring in relation to the embodied carbon of buildings. In a circular economy, the carbon footprint of a non-bio-based material becomes less negative over the cycle of its life.

Industry Resources

FEA’s Housing Dashboard

Virginia Tech's Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.

September 2022 Reports (released in November 2022)

Part A: September Housing Commentary

Part B: September Economic Conditions