HIGHLIGHTS

PROGRAM UPDATES

Wood on Wheels: Interactive Exhibit Showcases Possibilities of Wood The AWC and ICC Release New Wood Design Examples WoodWorks Contributes to New LEED Gold Building at UC DavisINDUSTRY NEWS

USDA Forest Service Releases New Infographic Touting Carbon Benefits of Forests North America’s Tallest Wood Building Adds Two More Stories Prefabricated, Mass Timber Building System Earns High Marks in Fire Testing University of Arkansas Researchers Study Behavior of CLT Panels in New Residence Hall Commercial Use of CLT Grows New CLT Multifamily Housing Coming to British Columbia Andrew Waugh Brings Mass Timber Messaging to West South Central Audiences Texas Architect Championed First CLT Building in State Oregon State Celebrates Opening of Mass Timber Research LabINSIGHTS ON THE COMPETITION

Carbon-less Concrete Hits MarketProgram Updates

Wood on Wheels: Interactive Exhibit Showcases Possibilities of Wood

To celebrate 2019’s National Forest Products Week, the SLB launched the Think Wood Mobile Tour at the National Building Museum in Washington, D.C., on October 22. The interactive, museum-quality traveling exhibit showcases the environmental and economic benefits of wood products and their expanding potential for commercial, multifamily, and residential construction. The exhibit uses building models, kiosks, and multimedia tools to tell the story of wood from the forest to the market and to educate and inspire building professionals to build with wood. Recent code changes that allow for taller wood buildings make this a particularly opportune time to promote innovations in wood products.

“The Think Wood Mobile Tour provides a window into the possibilities of wood for developers, architects, engineers, and other stakeholders across the country,” said Ryan Flom, Chief Marketing Officer at the SLB. “Where most see just a tree, we see the future of the built environment.”

Next the Think Wood Mobile Tour will visit:

- Chicago, Ill., Oct. 28–30, at Council on Tall Building and Urban

Habitats 10th World Congress - Louisville, Ky., Nov. 6–8, Remodeling Show & Deck Expo

- Portland, Ore., Dec. 4–6, JLC Live Residential Construction Show

To learn more or request a tour stop, visit ThinkWood.com/tour.

The AWC and ICC Release New Wood Design Examples

The American Wood Council (AWC) and International Code Council (ICC) have jointly released the new 2015/2018 Structural Wood Design Examples publication to support the structural design of wood buildings. The guide features over 20 wood building examples using both allowable stress design (ASD) and load and resistance factor design (LRFD), as permitted by building codes. Examples range from simple to complex, and together they offer complete solutions for wood member design, connections, and shear walls, making the publication useful to code officials, designers, or any member of the building community seeking to gain a more complete understanding of wood design and construction.

Numerical solutions provided in the guide work under the 2015 and 2018 National Design Specification® for Wood Construction and AWC’s 2015 Special Design Provisions for Wind and Seismic and 2015 and 2018 Wood Frame Construction Manual for One- and Two-Family Dwellings, as appropriate. Each of these AWC standards are referenced in building codes.

The Design Examples guide is available to download free here. Physical copies will be available for purchase from ICC.

WoodWorks Contributes to New LEED Gold Building at UC Davis

WoodWorks recently provided technical support to the team developing the new, 32,000-square-foot Latitude Dining Commons on the campus of the University of California, Davis. The project, led by Otto Construction and HED Design, includes a 500-seat dining hall, a full commercial kitchen, multiple food platforms, and convenience options. The building’s design uses exposed wood structures, pitched roofs, and large expanses of glass to provide natural lighting. The building is expected to achieve a minimum LEED Gold certification and is the latest example of mass timber proving an optimal choice for America’s sustainability-minded college campuses.

Industry News

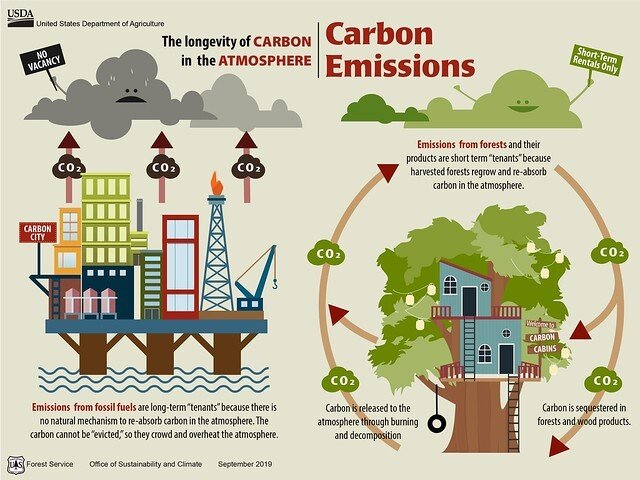

USDA Forest Service Releases New Infographic Touting Carbon Benefits of Forests

The USDA Forest Service recently published a new infographic to educate the public on forests’ critical ability to store carbon dioxide, even after trees have been sustainably harvested and converted into lumber, paper, and thousands of other commonly used products. Wood’s inherent carbon benefits are in sharp contrast to the emissions created by fossil fuels, which the atmosphere has no way of recycling, renewing, or regenerating.

The USDA notes that when people use wood-based products in place of fossil fuel-intensive products like concrete and plastic, there is a permanent benefit to the Earth’s atmosphere. For example, buildings framed in wood release 26 percent less carbon than steel-framed buildings and 31 percent less than concrete-framed buildings. If a wood house stands for 150 years, it will store carbon until it decays or is replaced. In that time, the forest will have regrown, resulting in additional carbon storage.

Read more about the comparative benefits of wood-based products here.

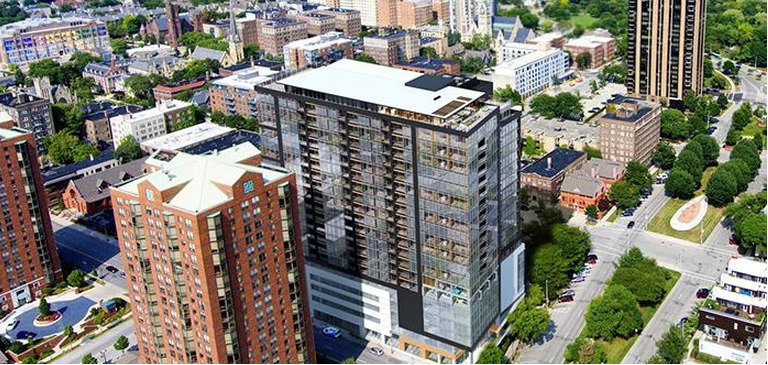

North America’s Tallest Wood Building Adds Two More Stories

Milwaukee’s planning commission recently approved changes to New Land Enterprises’ Ascent residential project, allowing the building to grow from 21 to 23 stories. The approved revision also adds 26 units to the project, bringing the total up to 231, and 50 more parking spaces, bringing the number to 301. The building’s 8,100-square-foot ground-floor commercial space was not affected by the changes.

WoodWorks and other tall wood advocates will be closely watching and eagerly awaiting the completion of Ascent, which, thanks to its height, will help the United States keep pace with peers in Europe who have been building tall with wood for over a decade and will breach the 21-story mark by the end of 2019. Ascent and other tall wood buildings in the United States are also important in helping to reinforce that tall wood buildings are as safe and perform as well as buildings made from other materials, while offering a more sustainable solution.

Read more about Ascent and its influence here.

Prefabricated, Mass Timber Building System Earns High Marks in Fire Testing

A Canadian firm has brought a new, prefabricated CLT building system to the market. Holz100 is a large construction made of large, high-quality moon wood CLT panels, which are connected only by beech wood dowels, not glue, nails, chemicals, or other adhesives.

The mass size of Holz100 takes advantage of the inherent fire resistance of heavy timber, with the surface layers charring and acting as insulating layers against the onset of heat to the inner layers of wood. The absence of chemicals and adhesives means that there is no additional fuel to further ignite fire or cause weakening from heat-induced delamination.

According to the manufacturer, a Holz100 house can withstand flames of 900 to 1000°C for 150 minutes without losing structural integrity; this exceeds all minimum time limits required by EU and UK building codes and makes the product roughly six times safer than reinforced concrete or stud-structured brick walls.

Read more about Holz100 here.

University of Arkansas Researchers Study Behavior of CLT Panels in New Residence Hall

A team of researchers from the Fay Jones School of Architecture and Design at the University of Arkansas is studying how the CLT used in the construction of the university’s newest dormitory, Adohi Hall, behaves when exposed to moisture. At 200,000 square-feet, Adohi Hall is the United States’ first large-scale mass timber residence hall and features two one-story podium buildings topped by four stories of CLT floor and ceiling panels and glue-laminated timber columns and beams.

Using a $100,000 grant from the U.S. Endowment for Forestry and Communities, the research team installed 135 wireless, battery-powered sensors on CLT portions of the building that are likely to be exposed to moisture, including in bathrooms, kitchens, the laundry, roof, and exterior walls. The sensors will take and transmit a moisture reading every 30 minutes, with the team analyzing collected data at the end of the first year and again after two subsequent years of data collection. Based on resistance measured, the team expects to be able to correlate the moisture content of each panel.

This research will help fill a current knowledge gap regarding the long-term effect of moisture on CLT and will influence future, broader use of CLT by design and construction professionals in the region.

Learn more about this research here.

Commercial Use of CLT Grows

Washington-based Fibre Federal Credit Union is building a new branch of its subsidiary, TLC Federal Credit Union, in Warrenton, Ore., featuring a CLT roof made with Douglas fir and glue-laminated timber posts and beams. Fibre Federal chose CLT as an affordable way to incorporate exposed wood, in keeping with the natural environment and character of the Pacific Northwest.

The posts, beams, and roof all came preassembled from KLH Massive Wood in Austria, which was contracted based on its ability to meet the project’s rapid timeline. The structure was erected in only two weeks and expects to be open for business in late 2019. Despite this project sourcing with a European supplier, analysts expect that European producers will increasingly lose their edge over the United States as more local mills come online. The global CLT market, valued at $670 million in 2016, is expected to grow to more than $2.3 billion by 2025, according to Transparency Market Research.

Read more about this project here.

New CLT Multifamily Housing Coming to British Columbia

British Columbia’s Adera Development Corporation has chosen CLT as the key material in its six-story, 72-unit Duet condo building currently under development as well as in its planned stacked townhouse project, both in Coquitlam. Adera chose CLT for the overall cost savings compared with concrete or standard stick-frame construction as well as for its environmental benefits, labeling CLT as “smart wood.”

Adera is confident that it will be able to transmit CLT’s cost savings on to consumers; it is currently preselling condos at the Duet project from $700 per square foot, which is considerably less than the price in new concrete condo towers in Coquitlam, which range from $850 to $955 per square foot.

Read more about Adera’s shift to CLT here.

Andrew Waugh Brings Mass Timber Messaging to West South Central Audiences

In early October, Andrew Waugh, a founding director of London-based Waugh Thistleton Architects, spoke at a symposium on design excellence in timber and wood hosted by the University of Arkansas’ Fay Jones School of Architecture and Design and the U.S. Forest Service. Following the symposium, Waugh was a featured guest on the Ozarks at Large radio program. During his radio interview, Waugh stressed that architects must play a leading role in the effort to combat climate change as buildings account for a large share of the planet’s carbon emissions. Waugh urged the building sector to focus on reducing emissions at the construction stage—by considering the materials used, process of construction, and maintenance—instead of the historical focus on the emissions associated with a building’s operations. Replacing concrete with timber is a key and immediate step the sector should make to cut carbon.

Listen to Waugh’s interview here.

Texas Architect Championed First CLT Building in State

RDon Powell, principal of the Dallas-based architecture firm BOKA Powell, recently discussed his own conversion to mass timber and its emergence in Texas in Commercial Real Estate. Powell was first turned on to mass timber several years ago following a conversation about Hines’ T3 mass timber office building in Minneapolis, which opened his eyes to the role of mass timber as a viable structural system for office buildings, hotels, and multistory housing.

Powell went on offense, next meeting with Texas firm StructureCraft to determine a pathway for constructing mass timber buildings in Texas. StructureCraft wisely saw a need for early engagement by mass timber designers and a need for turnkey delivery of timber components in order to alleviate schedule, cost, and quality concerns for prospective owners and developers. Powell continued to educate himself about mass timber construction, including structural bay sizes, column sizes, optimal beam depths, and how other building components can be adapted to work harmoniously with wood.

In early 2017, Powell earned his chance to build with wood, winning the commission to design the Soto, a six-story mass timber office building for Hixon Properties in San Antonio. The Soto is the first mass timber office building in Texas and features striking interior finished wood that sets it apart in the local office building market.

Read more here.

Oregon State Celebrates Opening of Mass Timber Research Lab

Oregon State University (OSU) recently celebrated the opening of the A.A. “Red” Emmerson Advanced Wood Products Laboratory, a new facility dedicated to researching and testing mass timber in commercial buildings. Located at OSU’s main campus in Corvallis, Ore., the 17,500-square-foot lab is part of the College of Forestry’s new Oregon Forest Science Complex, which broke ground in 2016.

The lab will house the TallWood Design Institute, a research collaborative between OSU and the University of Oregon that supports upward of 30 professors to study mass timber in tall commercial buildings, including as it relates to fire performance, building physics, and environmental impact. In 2018, Oregon became the first state to adopt building codes that allow for wood-framed buildings up to 18 stories tall. The new code changes and OSU’s investment in mass timber research and design serve as important harbingers for mass timber’s growth in Oregon and beyond.

Emmerson, for whom the lab is named, founded Sierra Pacific Industries in 1949. His son, George Emmerson, graduated from OSU in 1978 and is now the company president as well as chairman of the SLB.

Read more about the new center here.

Insights on the Competition

Carbon-less Concrete Hits Market

Concrete has come under sustained criticism for its disproportionate contributions to greenhouse gas emissions, and the industry is rapidly working to develop and bring to market greener versions of its products. Landscape Architecture Magazine recently provided an overview of several emerging technologies that are designed to improve the carbon footprint of concrete. Although many remain under development, some, including carbon sequestration in concrete and substantial reductions of cement using energetically modified cement, are now commercially available.

Read more about these products here.

Industry Resources

FEA Housing Dashboard

Virginia Tech’s Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.

August 2019 Reports (released in October 2019)

Part A: August Housing Commentary

Part B: August Economic Conditions