HIGHLIGHTS

PROGRAM UPDATES

The AWC Sponsors Second Annual Timber-Strong Design Build℠ Competition Think Wood’s “The Business Case for Building Wood” Creates Interest and DemandINDUSTRY NEWS

A Closer Look – Bright Future for Off-Site and Component Manufacturing Undersupply Anchors U.S. Housing Forecast New Framing Product Improves Thermal Efficiency Hands-On Learning Prepares Installers for Mass Timber Builds Remodeling Market Remains Strong for Foreseeable Future Sustainable Wood Products Play Key Role in Transition to Forest Economy Biophilic Benefits Add to Mass Timber’s Long-Term Value Proposition CLT Helps Contractors Overcome Skilled-Labor Shortages Arizona Set to Welcome First CLT Office Building Bethlehem Steel Tower Demolished USDA Leads Nationwide Celebration of HomeownershipProgram Updates

The AWC Sponsors Second Annual Timber-Strong Design Build℠ Competition

In April, 18 teams from colleges and universities in the western United States converged on California Polytechnic State University to participate in the second annual Timber-Strong Design Build competition, sponsored by the American Wood Council (AWC), the Engineered Wood Products Association, and Simpson Strong-Tie. The competition is designed to help engineering and design students gain hands-on experience in wood design and construction and learn more about the benefits of building with wood.

Competing teams built a 4′ x 6′ x 6′ structure over the course of 1.5 hours using lightweight wood frame construction; submitted material cost analyses, life-cycle assessment calculations, and structural designs to resist lateral and gravity loads; and gave short presentations on their structures. Each structure was subjected to a stress test, which included hanging 140-pound weights to the roof beam to demonstrate structural durability and vertical load.

While one team built its structure in only 77 seconds, others took the allotted 90 minutes. Creativity and innovation were common themes throughout, with one team even managing to incorporate a green roof.

At day’s end, a nine-judge panel awarded the team from Cal Poly San Luis Obispo’s Civil Engineering Department first overall, followed by teams from the University of Arizona and University of California, Los Angeles. You can learn more about the competition and its entries on the AWC’s YouTube page.

The AWC is currently working with partners to organize a national competition in November at the National Council of Structural Engineers Association’s Summit in Anaheim, Calif., to give more engineering and design students the opportunity to experience wood construction.

Think Wood’s “The Business Case for Building Wood” Creates Interest and Demand

Architect and developer interest in, and demand for, softwood lumber is created and honed through early and regular exposure to wood via marketplace trends, media, and continuing education. Think Wood has built a robust and engaging portfolio of continuing education unit (CEU) course offerings and was thrilled when its “The Business Case for Building With Wood” CEU was recently awarded the #1 Fastest Moving Continuing Education Unit Advertising Excellence Award from Architectural Record for garnering the most test-takers thus far in 2019.

The CEU overviews how light-frame and mass timber structural systems help developers maximize value and save time and money. It features several solutions that are newly available to specifiers thanks to recent code changes as well as common prefabricated and modular component and assembly options. The course also highlights wood’s many aesthetic and biophilic qualities.

In post-test surveys, the majority of test-takers indicated that they found the content interesting and useful, that they would recommend the course to colleagues, and that it gave them ideas they will apply to future projects.

Click here to download the CEU to read and share.

Industry News

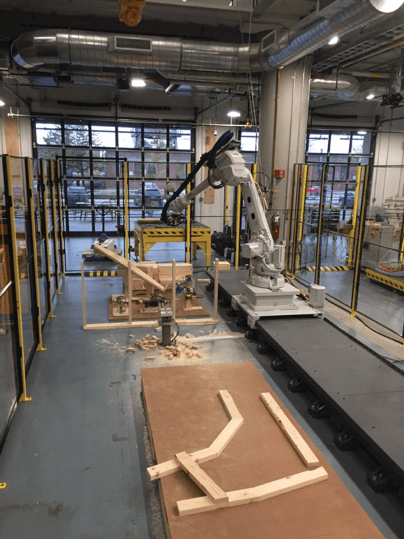

A Closer Look – Bright Future for Off-Site and Component Manufacturing

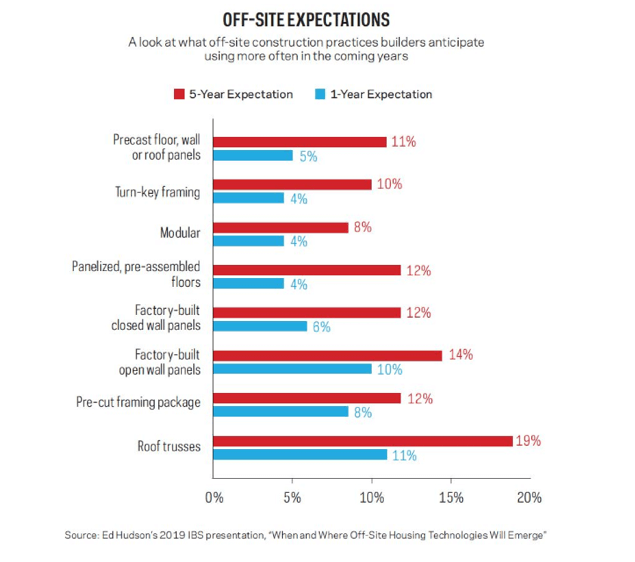

According to data and analysis assembled respectively by Home Innovations Research Lab and ProSales, both builders and dealers expect increased demand for off-site technologies and component manufacturing for the foreseeable future.

Both builders and dealers expect to see notable growth in roof trusses and open and closed wall panels, as builders increasingly transition away from rafter-frame roofs and site-built framing. Preassembled floors and prebuilt stairs are also primed for growth.

To date, the Midwest and West are quickest to adopt off-site construction, except when it comes to roof trusses, which see strong growth nationwide.

Undersupply Anchors U.S. Housing Forecast

Based on its in-depth analysis of market conditions, MetroStudy expects that the U.S. housing market will be stable, albeit undersupplied, throughout 2019, with high levels of pent-up demand in lower price ranges. Based on current permitting activity as well as overall economic conditions, forecasters expect to see a slow, gradual decline in housing starts after the market reached its recent peak of 1.23 million starts.

While there are some worrying signals—such as slower price appreciation, higher costs, upward pressure on mortgage rates, and slowed overall economic growth—they foresee little risk of market collapse because of undersupply and high demand in most markets. Though many markets are overvalued, few have developed a supply bubble.

To access MetroStudy’s complete Q2 Housing Forecast, click here.

New Framing Product Improves Thermal Efficiency

During a recent episode of the Build Show YouTube series, expert builder Matt Risinger introduced viewers to Tstud™, an innovative, newly engineered framing product that mitigates against thermal bridging. Each Tstud consists of an internal truss system and closed-cell foam that provide a near-complete thermal break in wall assemblies, thereby eliminating the need for exterior insulation. The product is code compliant with regard to strength, performance against wind loads, sound transmission, and fire safety. To learn more about Tstud visit https://www.tstud.com/ or watch the video.

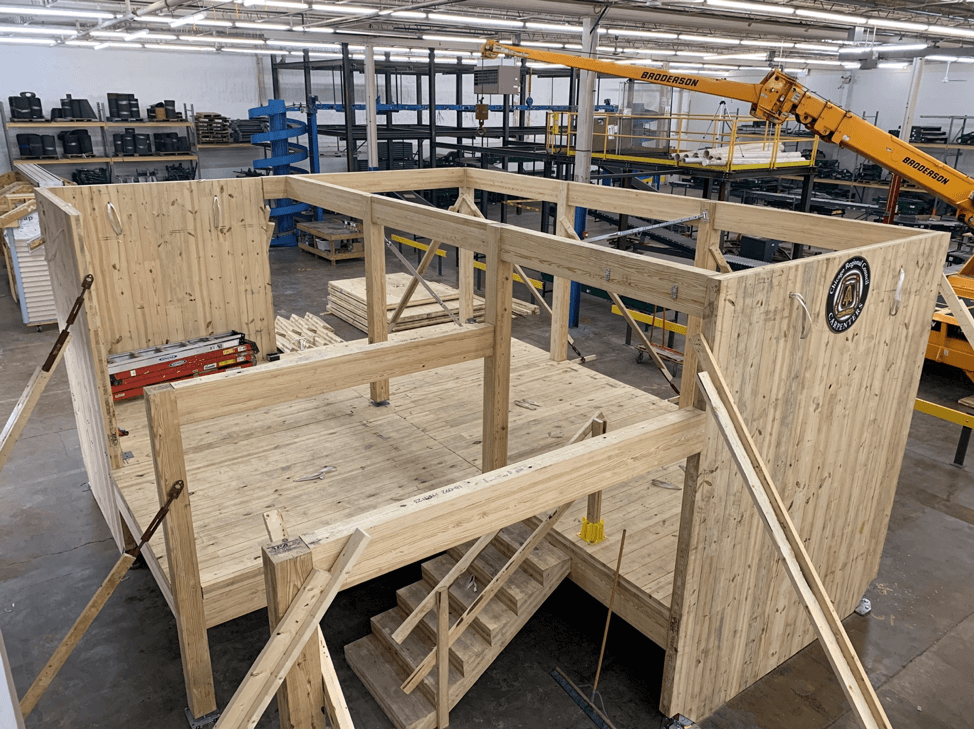

Hands-On Learning Prepares Installers for Mass Timber Builds

The Chicago Regional Council of Carpenters’ embrace of mass timber was recently featured in two episodes of the council’s Built to Last® television series. Built to Last® traveled to the council’s Apprentice & Training Center in Elk Grove Village, Ill., to see firsthand how the council is growing the capacity of current tradespeople to build with mass timber.

A centerpiece of the council’s mass timber curriculum is the opportunity for trainees to put together their very own mass timber structure. Working on behalf of the council, WoodWorks identified a manufacturer that created a customized CLT structure, which trainees assemble inside the training center. Besides giving trainees firsthand experience with the materials, the structure purposefully exposes them to a variety of scenarios that they may encounter in the field.

The council’s curriculum also emphasizes the role of installers as key members of design/build teams from the start. The council is working to share its mass timber training program with other training centers across North America to make sure a skilled workforce is in place and ready to build with mass timber.

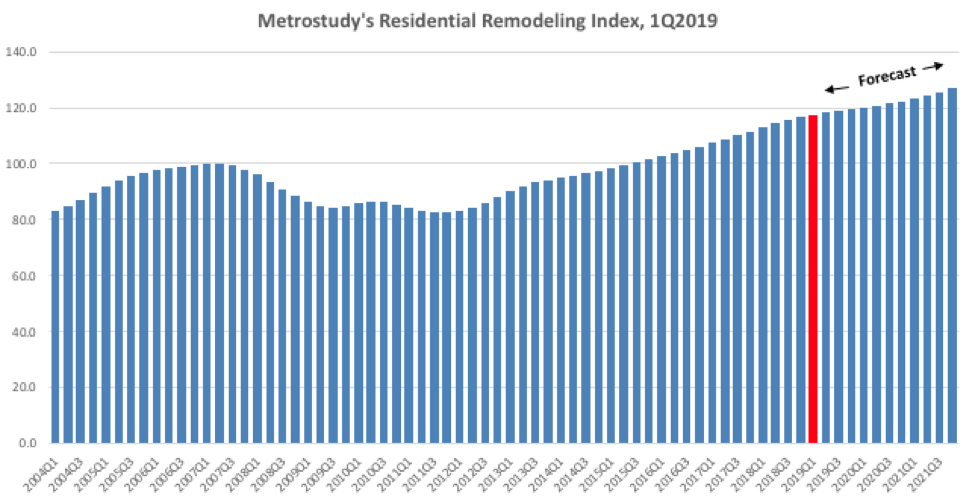

Remodeling Market Remains Strong for Foreseeable Future

The national Residential Remodeling Index (RRI) increased to a new high of 117.5 during the first quarter of 2019, marking a 4.1% increase from one year earlier and a 0.7% increase from the previous quarter. The RRI has now experienced 28 consecutive quarters of year over year gains. All but one metro area—Bismarck, N.D.—is expected to see growth in 2019 and at an average rate of 3.1%.

The inflation-adjusted value of big-ticket remodeling projects in 2019 is predicted to increase 4.8%, to $203.7 billion. Big-ticket exterior and basement projects are expected to have the biggest increases, while big-ticket pool, siding, and addition projects will have the smallest year-over-year increases.

While the latest RRI forecast projects continued growth over the next several years, it will slow compared with past years, with year over year gains dipping to approximately 2.3% in 2020 before rising again to 3.2% in 2021. These moderate gains will be closely tied to expected lower housing turnover. Read more here.

Sustainable Wood Products Play Key Role in Transition to Forest Economy

Bain & Company, a leading global consulting firm, recently teamed with the Nature Conservancy (TNC) to assess how reforestation can help address climate change. The result is a vision of a market-based forest economy that prompts reforestation at a fast-enough rate to slow climate change.

Rather than trying to reduce wood use, the envisioned forest economy emphasizes the increased use of sustainably harvested tree products, particularly for high-value, long-term uses. Demand for these tree products will be generated mainly by substituting wood products, such as CLT, for more carbon-intensive building materials like concrete and steel.

According to Bain’s analysis, a 1% increase in annual demand for industrial wood products could drive 20 million hectares of new sustainably managed tree farms.

To read more about Bain and TNC’s vision for a successful forest economy, click here.

Biophilic Benefits Add to Mass Timber’s Long-Term Value Proposition

Katerra, the California-based off-site construction company, recently published a white paper on mass timber’s role in achieving biophilic designs. Katerra noted that hundreds of existing studies already prove that exposure to natural elements, such as sunlight and natural materials like wood, has considerable positive impacts on human health and well-being, including when in indoor environments. Many people inherently feel better in interior wood environments, be it at home, at work, or in commercial or institutional spaces.

These biophilic benefits add to the overall economic cost-benefit of mass timber structures and make them more compelling as long-term, strategic investments. In the case of mass timber, biophilic benefits join a growing list of advantages, including shorter build times and cost savings compared with conventional construction materials and methods. Read more here.

CLT Helps Contractors Overcome Skilled-Labor Shortages

Like their peers nationwide, contractors in Portland, Ore., are shifting to prefabricated components as a way to increase efficiency and overcome the persisting shortage of skilled labor. In Portland, a bevy of new projects under construction incorporate panelized wood-framed wall systems, CLT panels in floor and ceiling installations, and other methods of prefabrication.

Computer-aided design and manufacturing ensure a high level of accuracy in the components themselves; however, project managers in Portland stress the importance of early planning and coordination to truly maximize the efficiency offered by prefabricated materials. With planning, on-site work and installations run more smoothly and thus minimize the amount of on-site work—and labor—required. Read more here.

Arizona Set to Welcome First CLT Office Building

Mortenson, in partnership with Urban Development Partners and RSP Architects, is developing and constructing Arizona’s first CLT office building, the five-story, 182,000-square-foot Beam on Farmer in Tempe. Located near Arizona State University, the Beam on Farmer will incorporate enough mass timber to capture 3.5 tons of carbon dioxide. Besides the carbon benefit, Mortenson specified CLT to improve the functionality of the building and maximize its interior design flexibility via large grid spacing and high exposed ceilings.

The Beam on Farmer will be available for occupancy in late 2020. Learn more here.

Bethlehem Steel Tower Demolished

In May, demolition crews imploded the 21-story, 332-foot Martin Tower, the former world headquarters of Bethlehem Steel. Built in 1972 during the height of the company’s heyday, the building was abandoned by Bethlehem Steel in 2003 during its bankruptcy proceedings.

Bethlehem-based Wind-Drift Real Estate and the Herrick Company currently own the 53-acre site and will turn it into a mixed-use development, featuring 578 housing units, 125,000 square feet of office space, and 100,000 square feet of retail. Read more here.

USDA Leads Nationwide Celebration of Homeownership

Throughout June, the U.S. Department of Agriculture (USDA) is celebrating National Homeownership Month and highlighting its role in helping residents in small towns and cities across rural America purchase affordable homes. Since 1949, USDA’s Single-Family Housing programs—which include a variety of loan and grant programs designed to increase access to homeownership—have served more than 4.4 million families in rural America, including in communities that are the cornerstone of America’s softwood lumber industry.

In kicking off the monthlong observation, Joel Baxley, acting assistant to the secretary for rural development, noted that “by helping rural Americans achieve the dream of homeownership, USDA is supporting benefits that extend far beyond the home, resulting in stronger, more prosperous rural communities.”

To learn more about National Homeownership Month, contact a USDA Rural Development State Office near you.

Insights on the Competition

Steel and Concrete Lament USDA Support of Wood Products

Several construction industry groups representing concrete and steel have written to the White House urging the National Economic Council to review the use of public funds to support projects that promote softwood lumber. Specifically, signatories take aim at the USDA’s awarding of more than $8.9 million in federal funds for 29 projects designed to expand markets for wood products, particularly mass timber, for building construction. While acknowledging the recent increase in CLT projects in the United States, the letter expressed concern about CLT’s performance on a large scale, irrespective of the rigorous data and testing that has supported mass timber’s acceptance into building codes. Read more here.

Steel Industry Casts Doubt on Methods to Measure Wood’s Sustainability

In May, the American Institute of Steel Construction released a white paper that calls into question the evidence used to assert wood products’ sustainability. The paper suggests that the wood industry selectively uses evidence and makes broad assumptions related to sustainable forest management, carbon sequestration, and wood waste to support its sustainability claims. In particular, the paper was critical of life-cycle assessments (LCA), asserting that LCAs can be valid only if comparisons are made between two buildings with identical requirements and configurations and by using a greater level of detail. Read more here.

Cement Industry Positions Itself as Key to Resilient Construction

The Portland Cement Association recently published a paper outlining how concrete can lead to more resilient construction than structures built with softwood lumber products. In its view, concrete’s resilience—based on how long it can last and its performance in disaster—translates into greater value in the long term.

The paper acknowledged the increased attention that wood construction has garnered in recent years due to innovations in mass timber, but portrays wood as a costly and less durable material compared with concrete.

The paper is also critical of building codes, asserting that codes focus on providing no more than a minimum level of safety. Read more here.

Steel Suited for Taller Modular Construction

Blair Hildahl of architectural and engineering firm Base4, which specializes in chain hotels, advocates for modular construction and believes that steel is optimal for mid- and high-rise multifamily, hospitality, and commercial structures. He notes that, because of steel’s weight, sophisticated and specialized connection mechanisms are required to build upward with modules to ensure uniform load bearing. In previous commentary, Hildahl had asserted that softwood lumber is a better fit for low- and mid-rise modular construction. Read more here.

Industry Resources

FEA Housing Dashboard

Virginia Tech’s Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.