HIGHLIGHTS

PROGRAM UPDATES

WoodWorks Pivots to Remote Services, Provides Uninterrupted Support Building the Low-Carbon Future The AWC Releases Update to Popular Span Calculator App Think Wood in Architectural Record California Promotes Innovation Through Mass Timber Competition SLB-Supported Mass Timber-Based Housing System Plan Unveiled in BostonINDUSTRY NEWS

Managed Forests Among Worthy Investments to Tackle Climate Change Katerra Project at Eastern Washington University Shows Potential for Carbon Neutrality NAWLA Launches Many Branches. One Industry. General Contractors Make Changes to Keep Up and Embrace Mass Timber Commercial Construction Simpson Strong-Tie Launches Free Online Pergola Planning Tool Construction Industry Shifts to Manufacturing and Mass Production Building Inspection Goes Virtual in Ohio HempWood Hits U.S. MarketINSIGHTS ON THE COMPETITION

Build with Strength 2.0 CarbonCure Lowers Embodied Carbon Without Adding CostProgram Updates

WoodWorks Pivots to Remote Services, Provides Uninterrupted Support

When news of U.S. COVID-19 restrictions broke, WoodWorks quickly pivoted its project support and education activities to online platforms – something its team was well positioned to do since the staff members commonly work remotely. WoodWorks also reached out to its clients, nationally and regionally, to let them know that WoodWorks is now available across multiple platforms and can provide uninterrupted services.

WoodWorks uses Zoom video conferencing to provide project support and conduct virtual “lunch and learns” so architecture, engineering, and construction professionals can continue to expand their knowledge of wood design.

The quarterly education offerings by WoodWorks will include two wood design symposiums and eight workshops, all locally relevant and delivered via online platforms. This is in addition to its existing, nationally focused monthly webinars.

Keep track of these and other upcoming virtual offerings here.

Building the Low-Carbon Future

Think Wood sponsored the Carbon Positive conference March 4-6, in Los Angeles. The conference – a “how to” for planning, designing, and building a low-carbon future, which drew more than 400 attendees – was organized by ARCHITECT Magazine and Architecture 2030. Speakers included representatives from Arup, Google, the Nature Conservancy, World Bank Group, Carbon Leadership Forum, Adrian Smith + Gordon Gill Architecture, MASS Design Group, and WoodWorks.

A founding sponsor, Build With Strength, hosted conference content on carbon-sequestering concrete. Think Wood’s continued sponsorship of industry-leading events ensures that wood’s message is front and center of trending conversations about carbon reduction from the built environment.

The AWC Releases Update to Popular Span Calculator App

The American Wood Council (AWC) has released an updated version of its free Maximum Span Calculator for Wood Joists and Rafters app, which includes updated design values for lumber as found in the 2018 National Design Specification® (NDS) for Wood Construction Supplement.

The calculator provides an easy way for designers, builders, and code officials to determine maximum allowable spans for lumber while working in the office or the field. Among its functions, the calculator can perform calculations for all species and grades of commercially available softwood and hardwood lumber, apply common uniform loading conditions, adjust for wet service conditions such as for outdoor deck joists, and enable users to compare multiple species and grades at a time.

The updated Span Calculator is available free in the Android, iOS, and Windows app stores. An updated, web-based version will be released this year.

Think Wood in Architectural Record

The March issue of Architectural Record featured a Think Wood category-exclusive editorial CEU sponsorship, written by the magazine’s editors. The piece, “Time for Timber,” spotlights the Billie Jean King Main Library in California, a SOM mass timber project and WoodWorks 2020 Wood Design Awards winner. Think Wood’s sponsorship included a full-page print ad and web banners next to the CEU course online. Several other articles in the March issue profiled wood building projects – including dormitories at the Rhodes Island School of Design, a youth hostel in South Africa, and the Catalyst building at Eastern Washington University – spotlighting innovative applications of mass timber and CLT in green building.

Reach the March issue here.

California Promotes Innovation Through Mass Timber Competition

California recently announced the winners of its first-ever Mass Timber Building Competition, which was administered by WoodWorks and organized under the state’s Forest Management Task Force. Winners include the California College of the Arts, Skid Row Housing Trust, Orange County Sanitation District, and Sunnydale Development Company; together their proposed projects represent nearly 325,000 square feet of new mass timber construction.

California’s goals in promoting mass timber through the competition comprised stimulating demand for mass timber buildings, generating investment in in-state production capacity, creating economic opportunities in rural areas, increasing affordable housing stock in cities, and advancing California’s climate change and green building objectives.

According to Jennifer Cover, President and CEO of WoodWorks, “Increased use of mass timber can benefit forest health and rural economic development, while reducing carbon emissions related to construction in California. The winning projects further highlight the design possibilities of timber and encourage wider adoption of its use throughout the state and across the country.”

Read more about the competition and benefits of mass timber here.

SLB-Supported Mass Timber-Based Housing System Plan Unveiled in Boston

A team composed of MIT architects and design and construction firm Placetailor recently revealed plans for a new five-story, mixed-use structure in Boston’s Roxbury neighborhood that will be both net-zero energy and made entirely of wood. The project’s design was supported by a U.S. Forest Service wood innovation grant in 2018 aimed at developing a mass timber-based system for midscale housing developments. The new, 14-unit Boston building will be the first demonstration of the system developed by MIT and Placetailor.

The building’s structure will be made from cross laminated timber (CLT), and it will be assembled on site mostly from factory-built subunits, which will optimize the building’s energy efficiency. The building’s net carbon emissions will be near zero and less than half that of a comparable building made with conventional steel or concrete.

Read more about the project, which was BLSC funded, here.

Industry News

Managed Forests Among Worthy Investments to Tackle Climate Change

When Amazon head Jeff Bezos announced that he was making a $10 billion commitment to fight climate change, The Fourth Generation blog immediately had ideas about how Bezos could maximize impact when it comes to removing CO2 already in the atmosphere – managed forests!

The blog, which is dedicated to climate and energy technology, asserts that planting more trees and managed forests are two important ways to sequester more carbon. Tree planting is often constrained by the limited supply of land available for afforestation because of urban development and agriculture. However, opportunities exist to intensify forest management to increase the amount of carbon sequestered. Managed forests on average sequester the equivalent of five to eight tons of CO2 annually per acre.

Read more here.

Katerra Project at Eastern Washington University Shows Potential for Carbon Neutrality

A recent piece in Architectural Record explores how designers and architects are better calculating and mitigating buildings’ embodied carbon emissions. While operating energy produces the majority of a building’s annual emissions, 11 percent comes from construction and material manufacturing and transport.

The piece takes a close look at the Catalyst Building, a 150,000-square-foot academic structure designed by Katerra for Eastern Washington University in Spokane. Catalyst uses CLT made from Katerra’s own nearby fabrication plant. In working to make the building as close to embodied-carbon-neutral as possible, Katerra analyzed and considered the environmental performance of the building and all components of the building’s supply chain, including forestry operations, lumber transport, energy sources, and steps involved in fabrication. This allowed Katerra to identify areas for improvement and make carbon-friendly adjustments.

In the end, Catalyst will be nearly embodied-carbon-neutral and will demonstrate the potential for more carbon-neutral small and medium-size structures.

Read more here.

General Contractors Make Changes to Keep Up and Embrace Mass Timber Commercial Construction

San Francisco–based general contractor Swinerton recently placed content in the San Francisco Business Times discussing the resurgence of wood in commercial construction, enabled particularly by the advent and growth of mass timber. In Swinerton’s view, mass timber offers important benefits to its clients, including sustainability, aesthetics, safer construction sites, cost savings, and outstanding performance in seismic zones.

To capitalize on the growth of mass timber, Swinerton has established a 25-person mass timber unit at its office in Portland, Oregon. To date, most of Swinerton’s mass timber projects have been in California and Oregon, but it is currently in the preconstruction phase for projects in Wisconsin, Texas, Georgia, Colorado, and North Carolina.

Read more here.

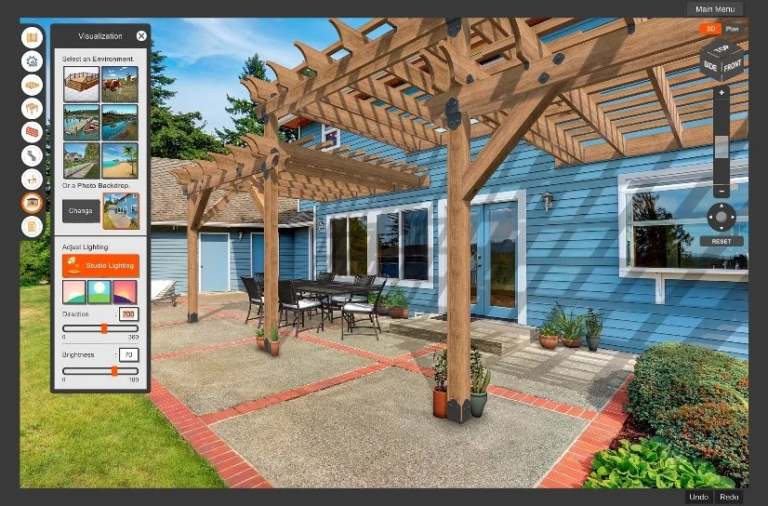

Simpson Strong-Tie Launches Free Online Pergola Planning Tool

Simpson Strong-Tie has launched a free online Pergola Planner Software™ tool to help contractors, lumberyards, and homeowners conceptualize and design pergolas and other backyard improvements. The free web-based tool features 3D software, design guides, an in-app user tutorial, and other tools and resources for designing and building strong, safe pergolas and outdoor spaces.

Read more about the tool here.

Construction Industry Shifts to Manufacturing and Mass Production

The online engineering community, Interesting Engineering, recently looked at how the building design and construction industry is shifting to wide-scale, mass-production techniques to keep pace with the demands of a growing human population. They point to an increase in relatively rapid prototyping and the development of premanufactured, block-construction systems that can be assembled to create large-scale and customized structures as key solutions. An important differentiator to these emerging mass-production techniques is that they can still deliver architectural beauty and originality.

Read more here.

Building Inspection Goes Virtual in Ohio

Building inspections in five western Ohio counties spread over 2,200 square miles have gone online through a new Virtual Inspection Program. Launched in April 2019, the program allows inspectors to optimize their time spent on inspections versus traveling between sites. Using iPads and iPhones and free applications like Skype, inspectors connect with contractors and review concrete slabs, light pole bases, foundation walls, insulation, and ice guards, as well as conduct re-inspections and above-ceiling inspections. Foundations and electrical work still require on-site inspections.

These counties’ shift to virtual inspections seems particularly prescient now in the time of coronavirus. The Miami County team anticipates that it will be able to conduct 75 percent of inspections using the Virtual Inspection Program during pandemic shutdowns.

Read more here.

HempWood Hits U.S. Market

This winter, California-based Reel Lumber introduced to the U.S. market HempWood, a new quasi-wood product derived from Kentucky-grown hemp. HempWood is manufactured via a patented process that uses bio-mimicry to transform hemp fibers and protein-based bonding agents into a product similar to oak. A key difference between hemp and oak and other hardwoods is their growth rates—it takes only five months to cultivate a hemp plant from seed.

Read more about HempWood here.

Insights on the Competition

CarbonCure Lowers Embodied Carbon Without Adding Cost

CarbonCure is gaining ground as a solution to cut concrete’s embodied-carbon footprint, thus making it more appealing to the growing number of designers, builders, and consumers who prioritize sustainability.

CarbonCure starts with CO2 captured from fertilizer and ethanol plants and in essence carbonates concrete, which both keeps the CO2 out of the atmosphere and makes the concrete stronger, which in turn reduces the amount of carbon-intensive Portland cement needed to achieve a specified strength. To date, nearly 200 concrete plants in North America and Singapore are using CarbonCure’s process, together trapping or eliminating about 125 million pounds of CO2 without added cost.

Read more about CarbonCure and other emerging concrete technologies here.

Industry Resources

FEA Housing Dashboard

Virginia Tech’s Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.

February 2020 Reports(released in April 2020)

Part A: February Housing Commentary

Part B: February Economic Conditions