HIGHLIGHTS

PROGRAM UPDATES

Mass Timber Code Adoption Continues With AWC Support Think Wood Partners on CEU Event to Educate Structural Engineers WoodWorks Makes It Easier to Perform Whole Building LCAs 2023 Timber Education Prize Helps Future ArchitectINDUSTRY RESOUCES

Virginia Tech's Monthly Housing ReportProgram Updates

Mass Timber Code Adoption Continues With AWC Support

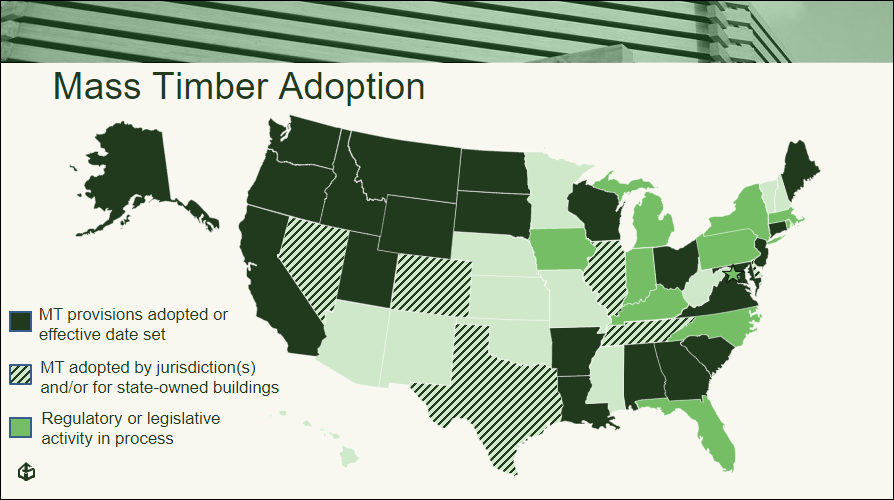

Mass timber construction continues to gain traction in the United States, with more states adopting the 2021 International Building Code (IBC) provisions for tall mass timber as the AWC engages in education and outreach efforts across the country.

Currently, 28 states have adopted the 2021 IBC mass timber provisions in either the entire state or in certain jurisdictions, up from 21 in 2022. The latest states to join the movement are Ohio and Tennessee. The Ohio Board of Building Standards recently approved the code package to adopt the 2021 IBC, set to take effect next March. The AWC was a regular participant in the Ohio Building Codes Committee meetings supporting the development of the approved code package.

Nashville, Tennessee, went a step further and approved a new ordinance to adopt the 2021 IBC provisions for mass timber ahead of statewide adoption next year. The District of Columbia is also making progress in adopting mass timber code provisions. The region’s Construction Codes Coordinating Board has begun the regulatory process by approving several code changes related to mass timber.

The AWC continues to provide support and expertise to other jurisdictions. The AWC recently presented “Mass Timber in the IBC” at the North Carolina Building Officials Inspectors Association. North Carolina is on track to adopt the 2021 IBC without modification by 2025.

At a local level, a ban on Type IV (heavy timber) and V (light-frame) construction officially expired in the City of Los Angeles. The AWC has been working to educate local business owners and council members about the safety and benefits of wood construction.

Taken together, these efforts represent a significant opportunity for both light-frame and mass timber construction to grow in new markets across the country. The work will continue: According to Forest Economic Advisors, moving the remaining states to the 2021 IBC represents an incremental opportunity of 2 BBF of lumber.

Think Wood Partners on CEU Event to Educate Structural Engineers

Structural engineers learned more about how wood could reduce their projects’ carbon footprint through real-world examples, thanks to a Think Wood partnership with the National Council of Structural Engineers Associations.

The sponsored continuing education webinar titled ‘Wood: Maximizing the Sustainable Benefits’ included an introduction by Katie Gerfen, Think Wood’s Director of Communications, and a lead speaking opportunity for WoodWorks President and CEO Jennifer Cover. The panel also featured Greg Kingsley, President and CEO of KL&A Engineers and Builders, who has brought a strong focus on mass timber to his firm, and Michaela Harms, Senior Director of Mass Timber at Sterling Structural.

The Q&A segment of the webinar was particularly engaging, with attendees asking detailed questions to better understand embodied carbon in the context of mass timber construction. The engagement demonstrated a deepening knowledge base on the topic among the audience of structural engineers. Think Wood followed up with a targeted email to the 300 event registrants that featured links to Think Wood sustainability resources and case studies, helping the engineer audience to continue their education on mass timber and sustainability topics.

WoodWorks Makes It Easier to Perform Whole Building LCAs

Whole building life cycle assessments (WBLCAs) are one of the best ways to quantify a building’s environmental impacts, but they can also be confusing and raise questions for design teams.

“In theory, doing a WBLCA sounds very straightforward,” says WoodWorks Technical Director Ashley Cagle. “Do a material takeoff, plug those numbers into your LCA tool, run the analysis, and boom—you’re done! But in practice, quite a few questions arise early in the process.”

WoodWorks’ latest resource, Considerations & Worksheet for Structural WBLCA of Mass Timber Buildings, is aimed at answering those questions and showing the positive impacts of mass timber buildings. It outlines international LCA requirements, provides guidance on how WBLCAs for mass timber buildings can be carried out using commercially available tools, and steps through common decisions that need to be made. It is complemented by a worksheet that designers can use to guide their own LCA process.

“The goal of the worksheet is to outline these decision points so designers can be better informed during the planning stages of an LCA—and to provide guidance throughout the LCA process on how to answer these questions for mass timber buildings,” says Cagle in a Q&A on this resource. The document is one of a growing number of WoodWorks resources helping to lower the barrier to adopting low-carbon mass timber construction.

2023 Timber Education Prize Helps Future Architect

Winners have been announced for the 2023 Timber Education Prize, an initiative sponsored by the SLB in partnership with the Association of Collegiate Schools of Architecture to recognize architecture faculty for their effective, innovative courses and curricula that create stimulating and evidence-based environments for learning about designing with timber.

Winning courses were submitted by educators at the University of Arkansas, the University of Cincinnati, the University of Washington, the University of Nebraska-Lincoln, the University of Texas at Austin, and the University of Maryland.

The prize creates incentives for schools to expand their wood-focused curriculum offerings as winners must teach the course at their host institution in the next two years. The developed course content will then be made available for other schools to adopt and further implement.

The “Time for Timber” submission (pictured above) from Tyler Swingle, a lecturer at the University of Texas at Austin School of Architecture, for example, says that the uniqueness and variety of wood as an architectural material and a building resource is underused and underdeveloped. “Rather than conforming to conventions, students will prototype, digitize, and develop new formal and performative designs that emphasize the unique material characteristics of wood and speculate on new timber construction standards,” the entry says.

The SLB’s Timber Education Prize not only recognizes leaders in wood education, but also helps ensure wood is top of mind for future architects as an innovative, sustainable material of choice.

Spotlight

Industrial Warehouses Make Up a Growing Opportunity for Wood

Industrial warehouses and big box facilities are a growing opportunity for wood construction, a trend documented by the 2023 industry forecast from Forest Economic Advisors.

L’Oréal’s new Research & Innovation Center in Clark, New Jersey, is a prime example of this trend. In an article on its website, construction management firm Structure Tone describes its work to install 90,000 square feet of CLT decking on the $140 million multiphase project, which includes structural additions of 90,000 square feet and 10,000 square feet and a 135,000-square-foot renovation. For L’Oréal, sustainability was the primary motivation for using CLT—and there are plenty of potential environmental benefits, from reducing emissions to sustainable sourcing to reducing waste, explains Structure Tone Project Executive David Adams.

“We are proud to work with L’Oréal in creating a space that reflects the company’s dedication to responsible innovation,” Adams says. “We share these values and will undoubtedly apply the insights gained from this experience to our future projects.”

Last October, Affinius Capital and Seefried Industrial Properties completed a 161,000-square-foot mass timber warehouse outside Dallas, among the first of its kind in the country. Affinius plans a similar project in Northern California, while outside Toronto, Prologis is building a 250,000-square-foot wood-framed warehouse with walls made of a concrete substitute, a new design it could roll out in other markets.

“The two companies are pioneers in a warehouse construction industry that’s a voracious consumer of concrete, a problem for developers and tenants concerned about climate change,” wrote Alby Gallun in Urban Land earlier this year. “The cement industry accounts for about eight percent of global carbon emissions annually, even more than aviation.”

“That’s a pretty staggering number, when you think about it,” Josh Hullum, Executive Director of Construction at San Antonio, Texas-based Affinius, formerly known as USAA Real Estate, tells Gallun. “The whole thesis was how do we remove concrete? We wanted to get to the root of how we could truly make a difference.”

The sector is a growing opportunity that the SLB and its programs will continue to pursue and support through technical support and resources. WoodWorks supported 23 factory/industrial buildings in 2022, up from 14 warehouses in 2021.

Industry Resources

Virginia Tech's Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.

July 2023 Reports (released in September 2023)

Part A: July Housing Commentary

Part B: July Economic Conditions