HIGHLIGHTS

PROGRAM UPDATES

WoodWorks Teams With Carpenters Union to Build Mass Timber Installation Capacity Improving Perceptions and Growing Wood Design Capacity AWC’s 2015 Deck Guide Now Available in SpanishINDUSTRY NEWS

Wood Makes Way Into 3D Printing Revolution Promoting Forest Products Careers to a New Generation CLT Creates Greener Warehouse Development in Tacoma, Washington North America’s Largest Mass Timber Building Under Construction Wood Skyscraper Figures Into Envisioned Chicago Redevelopment Ask This Old House Explores Machine-Built HousesINSIGHTS ON THE COMPETITION

American Institute of Steel Construction’s New Marketing Campaign With Competitive Advantages Setting the ToneProgram Updates

WoodWorks Teams With Carpenters Union to Build Mass Timber Installation Capacity

WoodWorks is partnering with the Chicago Regional Council of Carpenters Apprentice and Training Program to provide mass timber installer training to construction professionals in the greater Chicago area starting in 2019. The program will help ensure the availability of experienced construction professionals to meet increasing demand for buildings made from cross laminated timber (CLT) and other mass timber products. It will also serve as a model for training programs across the United States.

This initiative is part of a broader WoodWorks effort to support mass timber and other wood building-related training, which will focus initially on developers, union, and nonunion installers, and those involved in preconstruction and project management. WoodWorks will also oversee a networking website as part of its Professional Affiliate Program to connect individuals who have undergone training with those putting together project teams.

Improving Perceptions and Growing Wood Design Capacity

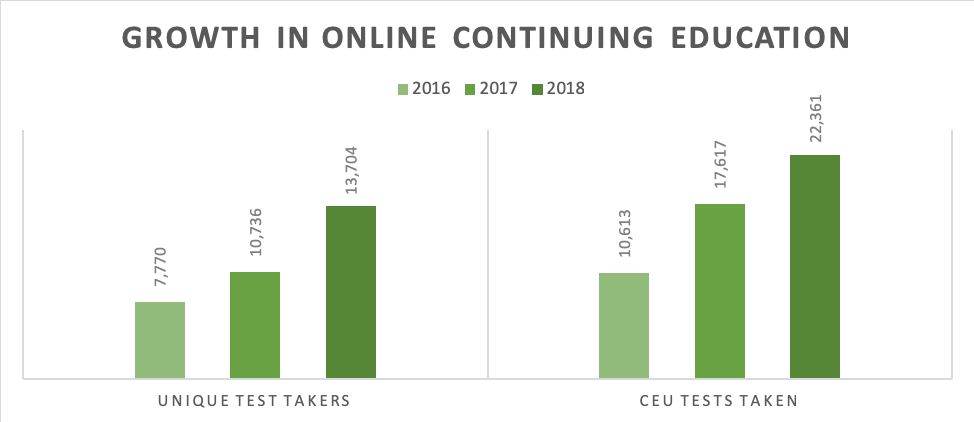

*Each test is one credit hour. Test-taker hours equal total tests taken.

In 2018, Think Wood developed seven new online continuing education units (CEUs) as part of its ongoing effort to respond to knowledge and perception gaps about wood in the design community. New and existing courses drove a 25% year-over-year increase in test-takers and tests taken compared with 2017, as well as a 66% increase in the number of individuals taking three or more tests.

Think Wood’s three most popular CEUs during 2018 were:

- Structural Wood Building Systems – Choosing the Right Material for a Sustainable, Safe, and Resilient Project, which gives an overview of the benefits accrued by using light frame and mass timber structural systems, including opportunities to maximize value through increased square footage;

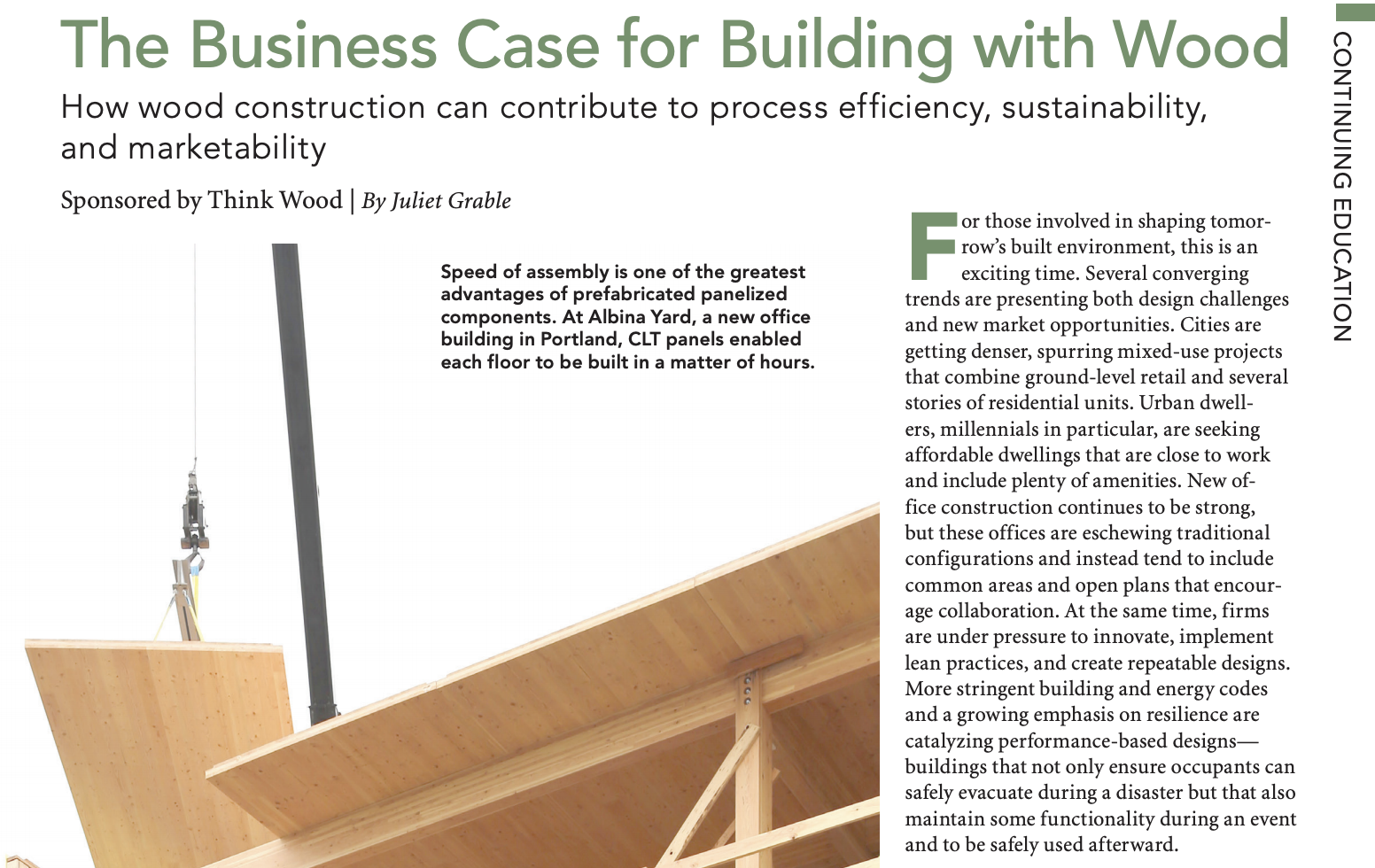

- The Business Case for Building with Wood, which describes how wood construction can be used to reduce construction time frames and simultaneously create environments that appeal to a new generation of employees and occupants;

- Designing Sustainable, Prefabricated Wood Buildings, which demonstrates the advantages of building with prefabricated wood components in terms of speed and efficiency of construction, design flexibility, environmental performance, and more.

- Think Wood is working with other SLB programs to leverage and integrate educational offerings to create comprehensive digital education experiences for users and enable knowledge tracks by profession, material, and application

AWC’s 2015 Deck Guide Now Available in Spanish

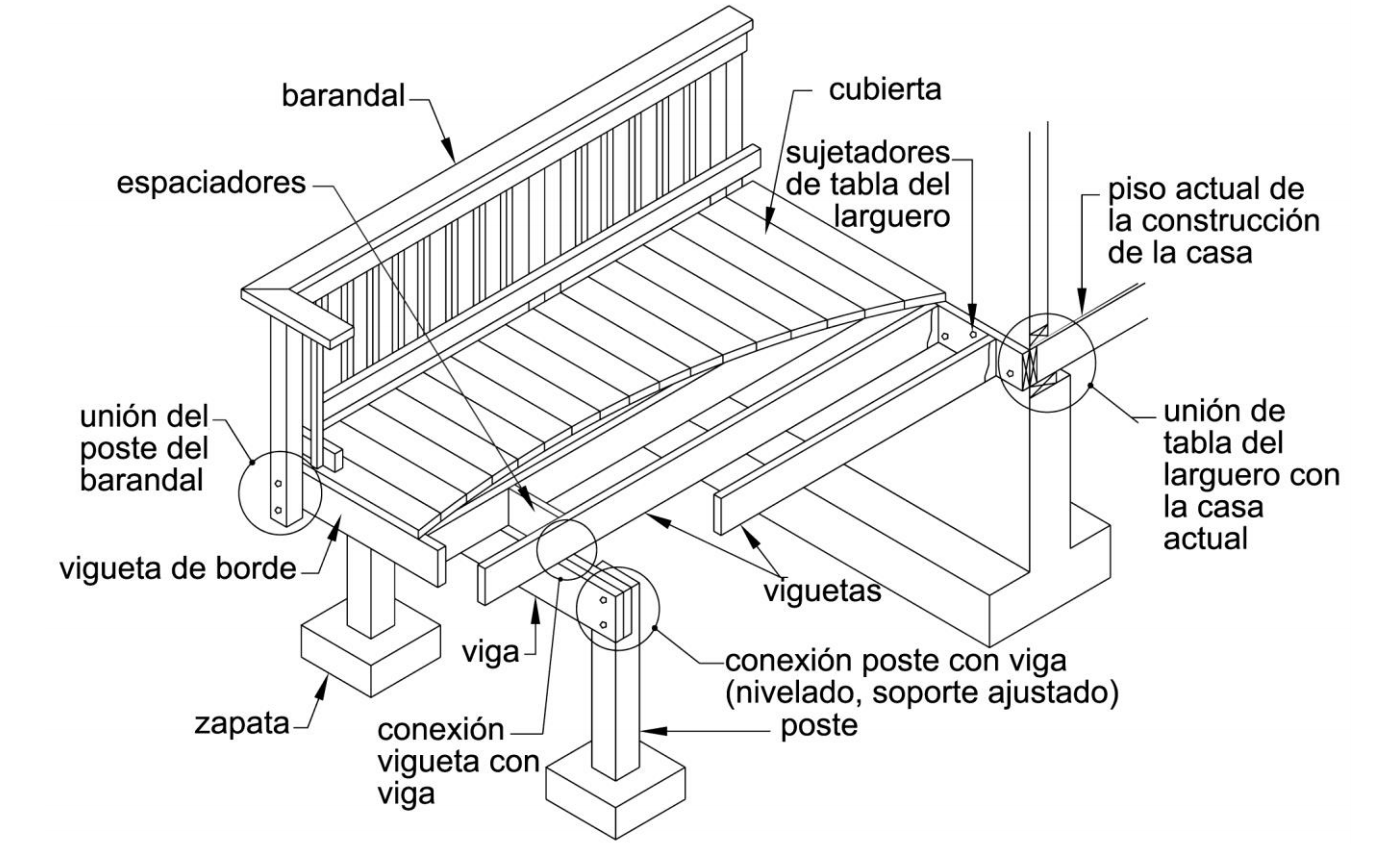

The American Wood Council (AWC) recently published a Spanish translation of the Prescriptive Residential Wood Deck Construction Guide: Design for Code Acceptance (DCA) #6 – 2015 IRC Version. DCA-6 contains important information on all elements of safe, code-compliant deck construction, including beam and joist span tables and a typical plan-view drawing. By using the guide, designers and builders are sure to create wood decking projects that meet current codes’ provisions for safety.

In 2018, over 43,000 copies of DCA-6 were downloaded in English. As it had done previously for the 2012 IRC Version, The AWC created a Spanish translation of DCA-6’s 2015 edition to help as many members of the deck design and construction community as possible access the guide.

The guide can be downloaded for free in English or Spanish at: https://www.awc.org/codes-standards/publications/dca6.

Industry News

Wood Makes Way Into 3D Printing Revolution

Canadian bioplastic company Advanced BioCarbon 3D (ABC3D) has developed wood-based bioplastic material that can be used in engineering applications and 3D printing. The material is made from resin that is extracted from waste wood cut down during wood collection by forestry companies and then added to the plastic to give it heat- and moisture-resistant properties.

The development of this wood-based product is part of ABC3D’s growing commitment to address climate change and other environmental concerns by developing products based on the sustainable use of renewable and biodegradable resources, such as wood.

Promoting Forest Products Careers to a New Generation

Veterans of the softwood lumber industry are increasingly stressing the need for the industry to market itself better in order to attract top talent, noting that many outside of the industry do not realize the diversity of career opportunities the industry offers. Whether finding creative ways to get wood products to market, build out supply chains, or develop new technologies that increase wood’s remarkable sustainability and value propositions, there are ample opportunities for top talent to effect industry-altering innovation, find satisfaction, and enjoy a rewarding career.

CLT Creates Greener Warehouse Development in Tacoma, Washington

CLT features prominently in a new 10,000-square-foot warehouse coming to the market in the Nalley Valley industrial area of Tacoma, Washington. The property owner chose CLT manufactured by British Columbia’s Structurlam Mass Timber Corp. for the building’s walls in order to make the project greener and more innovative than typical metal siding or concrete tilt construction. The warehouse will be available for occupancy in late February and is currently on the market for $2.9 million or for lease at $15,000 per month.

North America’s Largest Mass Timber Building Under Construction

A major technology firm is expanding its corporate campus in Silicon Valley with a focus on creating a sustainable workspace community. The updated campus will house 2,000 employees across two existing, repurposed building that are being integrated with a new 645,000-square-foot office building constructed primarily of CLT. The new structure, which will also be customized to meet ambitious sustainability goals related to energy and water use and emissions, will become the largest mass timber building in North America upon completion.

While the project team, representing architects WRNS Studio and structural engineers Holmes Structures, selected CLT for its low carbon footprint and inviting aesthetics, it is also enjoying the expedited construction schedule that CLT makes possible. Mass timber supplier Structurlam designed custom panels that can be quickly dropped into place onsite. Meanwhile, the project’s composite CLT-concrete slab allows the CLT panels to span farther between beams and columns, creating more open and inviting interiors.

Wood Skyscraper Figures Into Envisioned Chicago Redevelopment

Global architecture firm Perkins + Will and Cambridge University’s Natural Material Innovation project have teamed up to advance their vision of a wood skyscraper. Perkins + Will is working to develop a master plan for an area in Chicago’s downtown just west of Grant Park. They used this opportunity to also identify a real-world site and conceptually develop a tall wood building, the 800-foot River Beech residential tower. The Cambridge team supports the project by testing the structure’s various parameters in the lab.

While River Beech remains purely conceptual, the team’s point is to prove that the idea can work. For Perkins + Will, wood’s weight, greater flexibility, and ease of use make it an attractive potential substitute for steel and concrete in tall buildings.

Ask This Old House Explores Machine-Built Houses

In his “FutureHouse” segment, Ask This Old House home technology expert Ross Trethewey recently featured a custom homebuilder in New Hampshire to learn more about automated home construction. The longtime successful builder has been investing in automated manufacturing and design technologies to bring more high-performance, energy-efficient, and affordable homes to more people. The segment walks through the firm’s impressive operations in its 110,000-square-foot production facility, from customizing home designs using a standardized kit of parts to digital carpentry, offsite fabrication, and eventual assembly, which takes just three to four days onsite. Engineered materials, including engineered wood, are preferred throughout the process as they allow for greater precision and efficiency.

Insights on the Competition

American Institute of Steel Construction’s New Marketing Campaign With Competitive Advantages Setting the Tone

The American Institute of Steel Construction recently launched a new advertising campaign to assert steel’s comparative advantages when it comes to environmental sustainability. The ad’s positive tone, evocative imagery, and use of data mark a notable shift from the fear-mongering ads that the concrete industry recently lobbed at wood. The SLB regularly tracks wood’s share of voice and impressions compared with competing materials and will be on the lookout to see if this ad yields a bump in steel’s numbers.

Industry Resources

Virginia Tech’s Monthly Housing Report

This monthly housing commentary report is a free service of Virginia Tech and is intended to help one gauge future business activity in the U.S. housing market.

November 2018 Reports (released in February 2019)

Part A: November Housing Commentary

Part B: November Economic Conditions

A Closer Look – Building Trends: Mass Timber

Mass timber is no longer a concept used only elsewhere in the world. Curiosity is turning into learning and knowledge into expertise, leading to structures being built. As of December 2018, nearly 500 multifamily, commercial, or institutional projects have been constructed out of mass timber across the United States, or they’re currently in design or under construction.

For more detail on the types of mass timber being used, geographic breakdown, and more, click here.