HIGHLIGHTS

PROGRAM UPDATES

SLB Funded Program Review Think Wood Sets Record Straight, Corrects Misleading Competitor Messaging HGTV Personality Helps Wood, Naturally Increase Reach Stopping Construction Fires Mass Timber Code Coalition Touts Benefits of Mass TimberINDUSTRY NEWS

Mass Timber to Feature Prominently in Proposed NHL Seattle Ice Center 21-Story Wood Building Planned for Milwaukee Colorado School of Mines Explores Viability of CLT as a Protective Structure NLT and DLT Shine in TorontoINSIGHTS ON THE COMPETITION

Concrete Industry Misleads by Confounding Mass Timber With DeforestationProgram Updates

SLB Funded Program Review

Following the industry’s supermajority mandate for the Softwood Lumber Board and direction from the SLB’s Board of Directors, in August the SLB staff launched a funded-program review in order to refine, align, and optimize the organization’s investment strategy, tactics, and funded initiatives and to bring expenditures in line with revenues.

In September, SLB-funded programs submitted responses regarding their objectives, strategy, measurement assessment, tactics, and budgets, broken down by target audience, as well as their outlook for the next seven years. The staff has reviewed and analyzed the responses with the intent to improve program delivery, enhance the target audience experience, and create incremental demand for wood in the built environment. Funded programs will be presenting 2019 budgets and plans for approval at the November 28, 2018, SLB Board meeting in Washington, D.C.

The conditions and needs in 2018 are very different and more advantageous for lumber than they were when the SLB was established in 2011; therefore, the approach to delivering on its objectives needs to evolve in order to establish softwood lumber as the preferred choice for the built environment by 2024.

Think Wood Sets Record Straight, Corrects Misleading Competitor Messaging

Softwood lumber’s competitors are growing bolder in their efforts to discredit wood as they attempt to regain real or perceived lost market share. The impact of their misleading messaging has been negligible to date, thanks in part to the fast and thorough rebuttals of Think Wood, which confronts false information and corrects the record on behalf of the softwood lumber industry.

For example, in early 2018, Construction Executive published an article titled “Five Benefits of Using Steel Instead of Wood for Construction,” which was written by an employee of a pre-engineered steel building and component company. The article includes the misleading and unsupported claim that “building with steel is the epitome of sustainable construction” and argues against using softwood lumber, stating that “few forests in the United States are certified for lumber.”

Think Wood aggressively pushed for an opportunity to present a follow-up article to offer a counter perspective. That piece, “Attain Full Life Cycle Benefits by Building With Wood,” went live in September and provides referenced arguments for wood’s advantages compared with steel or concrete. The article integrates data and learning found in Think Wood’s continuing education units, developed and/or reviewed in conjunction with experts at the American Wood Council (AWC) and WoodWorks, and leaves viewers with little doubt over which material best supports sustainable construction.

Although competitors’ misleading claims are not consistently directed at nor necessarily resonate with those who specify structural materials, research shows that specifiers regularly engage with Construction Executive and similar platforms. This means that however egregious competitors’ statements or selective use of data may be, Think Wood will make every effort to present evidence-based, well-supported counterpoints to set the record straight.

HGTV Personality Helps Wood, Naturally Increase Reach

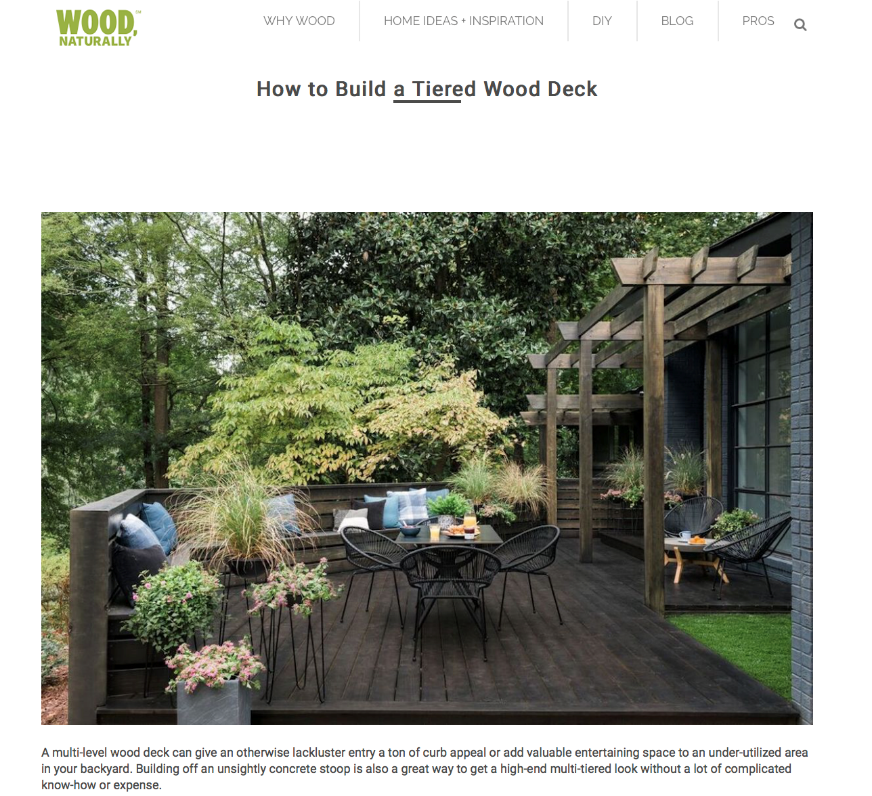

Wood, Naturally partnered with HGTV personality and DIY influencer Brian Patrick Flynn over the course of the deck season to lend credibility to the campaign’s pro-wood messaging while expanding its reach among target audiences. Wood, Naturally worked with Flynn to develop content and step-by-step guides for two common projects undertaken by homeowners and contractors—How to extend an existing deck and How to build a tiered-wood deck.

Content included blog posts, styled deck photography, and video content, and it was promoted across Wood, Naturally’s Facebook, Pinterest, and YouTube channels, generating more than 657,000 impressions, 17,300 clicks, and 2,700 user engagements in the form of comments, reactions, and shares.

Social media audiences were particularly moved by video and still images that captured the beauty and natural essence of wood. For example, a tiered entry deck blog received responses such as: “That’s the outside I’d love,” “Beautiful,” and “See how easy this is!” Partnerships like this one with Flynn are a proven way for Wood, Naturally to generate positive engagement from professional and homeowner audiences.

Stopping Construction Fires

AWC recently revamped ConstructionFireSafety.org, which provides a variety of educational content for fire-service and code professionals, builders, developers, and others involved in large-area construction. The site’s content now features the following:

- Risks & Hazards: Helpful information to assess on-site risks and safety practices for activities such as welding and hot work.

- Building Standards: National building standards from the International Codes Council and National Fire Protection Association and requirements to avoid construction fires, such as fire-lane layout plans and fire-watch policies.

- Best Practices: Practical resources on how to avoid construction fires, ideal for use when reviewing construction projects or providing safety trainings.

- Fire-Service Resources: Sample fire safety plans and checklists, Hot Work program templates, fire-suppression strategy and tactics, evacuation plans, and more.

AWC maintains the site on behalf of the Construction Fire Safety Coalition, which since its launch in 2017 has grown from six charter members to include over 40 partners, including the National Association of State Fire Marshals, the Fire Equipment Manufacturers Association, private companies, and local jurisdictions and fire departments.

From 2010-2014 construction fires accounted for less than 1% of all building fires nationwide; however, they often attract significant media coverage that can hurt the perception and future use of wood. The coalition is committed to reducing the number of fires to ensure that wood remains a viable option for larger buildings. Please refer a local building or fire official to ConstructionFireSafety.org today!

Mass Timber Code Coalition Touts Benefits of Mass Timber

The Mass Timber Code Coalition, supported by the American Wood Council, published a new infographic to highlight tall wood buildings’ fire resistance, structural integrity, environmental attributes, and cost efficiency ahead of the ICC Ad Hoc Committee on Tall Wood Buildings’ decision on code proposals that will allow wood buildings up to 18 stories. Key evidence in support of the proposals includes the following:

- Mass timber panels lasted 3 hours and 6 minutes during fire-resistance testing, exceeding the two-hour rating required by code.

- Mass timber buildings weigh approximately one-fifth as much as comparable concrete buildings, yielding a high strength-to-weight ratio that performs well during seismic activity.

- Replacing steel with mass timber can reduce carbon dioxide emissions by 15-20% with the same emissions-control effect as taking more than 2 million cars off the road for a year.

- Mass timber buildings are roughly 25% faster to build than concrete buildings.

The mass timber code coalition, which is made up of building officials, architects, engineers, builders, former fire-services officials, and materials providers, is constantly fending off false statements by the concrete industry, which seeks to strike down the proposals in order to protect its market share. Products like the infographic, which highlights independent, third-party research findings as well as quantitative outputs of testing done as part of the code-compliance process, are designed to help those in and outside of the building industry separate fact from fiction when it comes to evaluating the benefits of tall wood buildings.

Industry News

Mass Timber to Feature Prominently in Proposed NHL Seattle Ice Center

Perhaps inspired by the Washington Capitals’ recent Stanley Cup victory, the other Washington— Washington state—is keen to get in on the action. The NHL Executive Committee recently approved Seattle as home to the National Hockey League’s newest expansion team, with the first puck to drop as early as 2020.

The organization behind Seattle’s bid, NHL Seattle, is ready and recently announced plans for a $70 million, 180,000-square-foot headquarters and practice facility, which will be an anchor tenant of the soon-to-be-redeveloped, mixed-use Northgate Mall site. The hockey facility, which is being designed by Generator Studio of Kansas City, will make extensive use of mass timber, including stunning beamed ceilings in three ice rinks. The choice of mass timber seems natural for Seattle and a fitting nod to the healthy forests and robust forest industry of the region.

The NHL will make its final decision on launching a new team in Seattle in December. A look at the design plans of the wood Ice Center can be seen at https://www.nhlseattle.com/index.html.

21-Story Wood Building Planned for Milwaukee

Developer New Land Enterprises recently announced plans to build a 21-story, 410,000-square-foot apartment tower in downtown Milwaukee, which when built will become the tallest timber building in the Western Hemisphere. The project, called Ascent MKE, is the second mass timber building New Land is developing in Milwaukee in partnership with Milwaukee architectural firm Korb + Associates. For both projects, the team has chosen wood for its environmental benefits and one-of-a-kind design aesthetics.

New Land expects to begin construction on Ascent MKE in the fall of 2019 and complete it in the spring of 2021.

Colorado School of Mines Explores Viability of CLT as a Protective Structure

An unpublished study, Analysis of Military protective Structures: A Framework for Quantifying Cost-Benefit of Existing and New Protective Systems, by a graduate student at the Colorado School of Mines analyzed the cost-benefit of various protective systems used by the U.S. military, including bunkers built with cross laminated timber, reinforced concrete, and sandbags, based on the number of man-hours, machine hours, and costs involved. The study showed that CLT bunkers are feasible, requiring significantly fewer man-hours than berms with sandbags and offering more cost-efficiency than reinforced concrete. The conclusions presented here can serve as a starting point for civilian and military leaders to debate the effectiveness and suitability of new protection structure designs, additional research is recommended.

This study joins other recent research by U.S. military branches, including SLB-funded research on blast effects, into the use of CLT in military applications as the military looks to keep pace with technological advances in construction.

NLT and DLT Shine in Toronto

Designed by Quadrangle Architect, 80 Atlantic is Toronto’s first new timber-frame commercial building in a generation, made possible by recent changes in building codes that allow six stories of wood construction. The 87,400-square-foot mixed-use development features nail laminated timber (NLT) flooring planks dropped onto posts, and beams made of glue laminated timber (glulam) as well as exposed CLT ceilings.

While CLT generally gets more media buzz, 80 Atlantic shows off some of the comparative virtues of NLT, namely that it is less expensive, there are no glues, it can be made anywhere, and it has been in the building codes since they were written. When these mass timber products are combined in 80 Atlantic, the result is a building that has approximately half of the embodied energy of a totally concrete building.

Insights on the Competition

Concrete Industry Misleads by Confounding Mass Timber With Deforestation

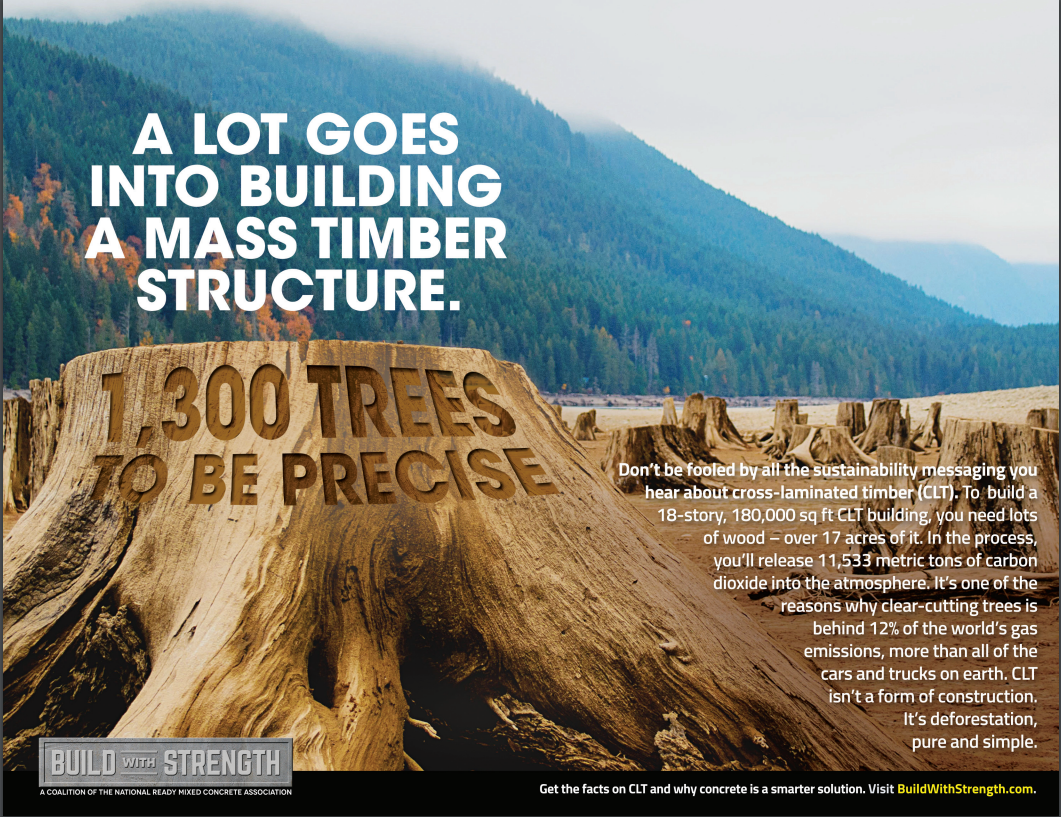

The concrete industry’s Build With Strength campaign continues to mislead the public on the impact of tree harvesting in the process of creating lumber and mass timber. Using what appears to be a Photoshopped image of a few tree stumps (with no undergrowth vegetation whatsoever) in front of a forested mountain, Build With Strength has published an infographic claiming that concrete buildings are more environmentally friendly than CLT. The graphic neglects to give the viewer a full understanding of how harvesting cycles work and relies on studies up to 24 years old. The graphic doesn’t substantiate questionable claims of benefits of concrete (“concrete surfaces absorb carbon dioxide throughout their lifetime,” “At the end of a concrete building’s usable life, concrete can be recycled”) and even tries to claim credit for building features that are not restricted to concrete construction, such as green rooftops.

Industry Resources

FEA’s Housing Dashboard

This housing dashboard is provided compliments of Forest Economic Advisors (FEA).

Virginia Tech’s Monthly Housing Report

August 2018 Reports (Released in October)

- Part A: August Housing Commentary

- Part B: August Economic Conditions